LASER PROJECTORS IN THE AUTOMOTIVE INDUSTRY

In the manufacturing of auto body parts, laser projectors help with the inspection of welds.

Textile

visualize nested parts and optimize material usage

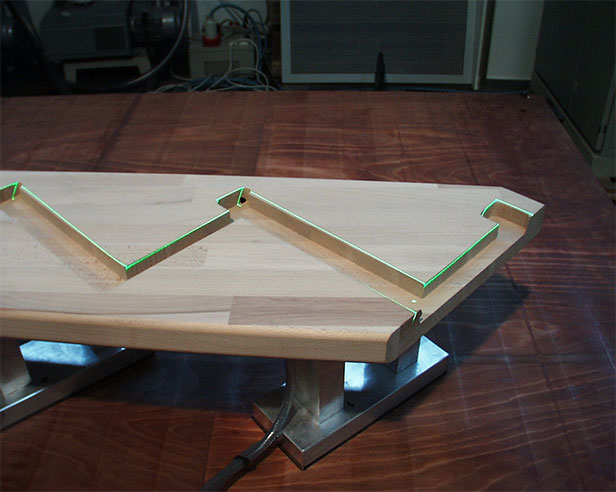

For textile cutting operations, projected laser light patterns aid in closely nesting parts to get the maximum out of each piece of raw material. The Laser Projector System allows the operator to see the relationship of the cutting tool path to the materials edges helping to make the most of all available material.

The projected patterns show where any irregularities in the material will fall with respect to the finished pieces so that part blanks can be rotated or positioned to minimize the impact of any defects. The patterns also show finished part orientation in relation to the materials grain or color pattern to help operators make the best choices when orienting the material prior to cutting.

For continuous cutting operations on long feed tables, Laser projected patterns help to position the rolls of material being fed into the cutter and make it easier to maintain alignment of the material as it is being fed out.

The use of Laser Projectors for aligning components in the welding of assemblies increases speed, accuracy and safety and enhances overall profitability by creating faster throughput with fewer errors...Learn More

Laser Projectors are used in CNC processing centers to optimally place part blanks and mechanical or suction based hold down devices quickly and accuractely to help minimize material waste and elimina...Learn More

Modern processing of stone using CNC based routers and saws requires precise alignment of hold-down fixtures and part blanks. Placing vaccuum holding fixtures using manual measurents is time consuming...Learn More