LASER PROJECTORS IN THE AUTOMOTIVE INDUSTRY

In the manufacturing of auto body parts, laser projectors help with the inspection of welds.

Stone Fabrication

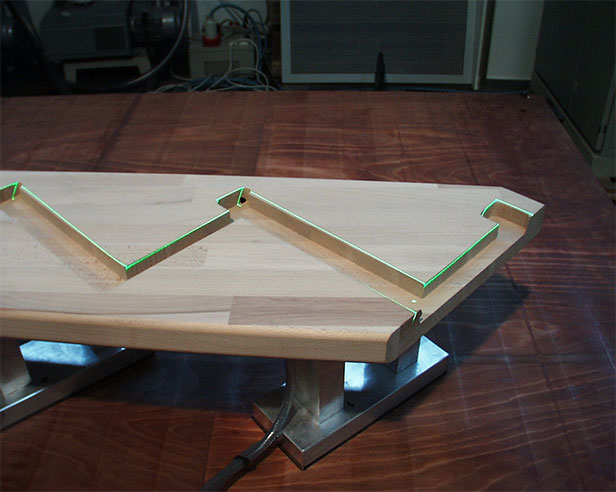

quickly position hold-down fixtures and part blanks

Modern processing of stone using CNC based routers and saws requires precise alignment of hold-down fixtures and part blanks. Placing vaccuum holding fixtures using manual measurents is time consuming, creates the possiblity of error and may expose the operator to the risk of working in close proximity to a moving router head. These costs and risks can be greatly reduced through the use of Laser Projector Systems. Expensive materials can be quickly and precisely aligned–for faster processing, higher quality, and less waste.

In stone processing, reducing the time spent in setting up the router table means more jobs through each machine each day – and that means more profit. Whether it’s granite or marble countertops, back splashes or vanities each job is unique. Placement of fixtures must be precise in order to prevent damage to the fixtures or the router. Each stone slab is unique and placement of the part blank must take into account the grain and defects present. The Laser Projection System can be used to show a clear outline of the fixture location making sure that the fixtures remain clear of the tool cutting path. The laser can also show the part outline, allowing the stone slab to be positioned to prevent any edge irregularities or surface defects from marring the finished product.

Even before reaching the CNC machining center, the Laser Projection System can offer significant benefits. If your shop is using electronic templating equipment the data for your project is contained in digital files and no phyiscal wood or paper template exists. In such cases the projector can input the digital data directly and project part shapes onto the stone where key cut points can be marked and used for guidance at the bridge saw, thus reducing consumables costs and eliminating measurement errors.

The superior, freely scalable LPM laser projection software supports the most widely used CNC formats as well as DXF. This allows contours to be transferred directly to the laser via the machine control and then projected in one-to-one size directly onto the machine working surface or top of the material being processed. Easily customized controls within the software allow the operator to quickly apply any required offsets in position or projection height to accommodate your operation’s unique requirements.

These systems feature:

They provide many advantages such as:

In addtion to the base control software, optional add-ons are available such as:

The use of Laser Projectors for aligning components in the welding of assemblies increases speed, accuracy and safety and enhances overall profitability by creating faster throughput with fewer errors...Learn More

Laser Projectors are used in CNC processing centers to optimally place part blanks and mechanical or suction based hold down devices quickly and accuractely to help minimize material waste and elimina...Learn More

Modern processing of stone using CNC based routers and saws requires precise alignment of hold-down fixtures and part blanks. Placing vaccuum holding fixtures using manual measurents is time consuming...Learn More