CNC Machining

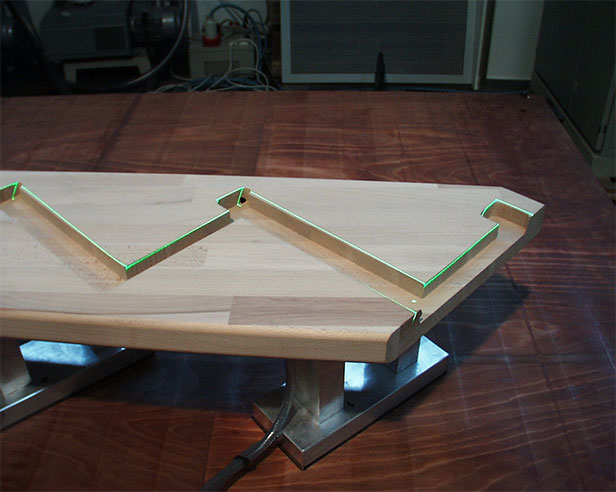

Laser Projectors are used in CNC processing centers to optimally place part blanks and mechanical or suction based hold down devices quickly and accuractely to help minimize material waste and eliminate damage to the machine or fixtures.

Heavy, valuable and sensitive materials such as wood, glass, composites and ceramics must be handled with utmost care. Mistakes and unnecessary waste create considerable costs. Using computer controlled Laser Projection Systems, these precious materials can be quickly and precisely aligned–for faster processing, higher quality, and less waste.

Whether your products are components for furniture, architectural components such as stairs, window frames or cabinet parts, or components for vehicles the use of lasers can reduce scrap, increase throughput and enhance worker safety. No matter if the material is wood, hard glass, special plastics, composites or structural foams the Laser Projection Systems can offer a strong advantage.

While aligning the workpiece, the laser facilitates the optimum utilization of the material by displaying the contours of the finished workpiece on the material. Production staff can then align the material for best utilization and to minimize the impact of any defects in the materials grain or form.

The superior, freely scalable LPM laser projection software supports the most widely used CNC formats as well as DXF. This allows contours to be transferred directly to the laser via the machine control and then projected in one-to-one size directly onto the machine working surface or top of the material being processed. Easily customized controls within the software allow the operator to quickly apply any required offsets in position or projection height to accommodate your operation’s unique requirements.

1.888.622.7837

1.888.622.7837